■ The traction crusher integrates crushing, conveying, and storage in a fully endlosed state to avoid pollution, save. labor, and meet environmental protection standards.

■ The machine is placed in the soundproof cover to ensure the reduction of noise when the machine is running.

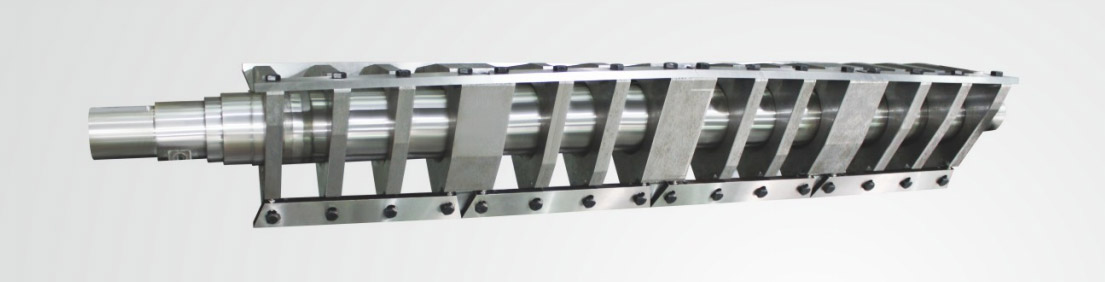

■ The uniquely designed rotor keeps the rotor's cutters in the best state during the process of crushing materials, reducing the generation of powder.

■ The thickness range of crushed and recydled scraps is 0.2-3.5mm.

It is suitable for PP PET, PS, PLA, PVC, biodegradable materials and other plastic sheets, plastic packaging (food, electronics, medica) forming scraps after punching and utting, and a small amount of defective products for crushing and recyding.

| Model | XMG 300/400 | XMG 300/600 | XMG 300/800 | |

| Drive power | kw | 7.5 | 11 | 15 |

| Traction power | 0.75*2 | 1.1*2 | 1.1*2 | |

| Number of rotor knives | 6 | 6 | 12 | |

| Static son tool number | 4 | 4 | 8 | |

| Rotor diameter | mm | Ф300 | Ф300 | Ф300 |

| Rotor width | mm | 820 | 1000 | 1280 |

| Manual feeding port size | mm | 600*200 | 1000*200 | 600*200 |

| Coil entrance size | mm | 800*125 | 1000*125 | 1270*125 |

| Crushing cavity diameter | mm | 300*820 | 300*1000 | 300*1280 |

| Screen aperture | mm | 10 | 10 | 10 |

| Weight | kg | 1318 | 1850 | 2160 |

| Dimensions | mm | 1800*1700*1350 | 2000*1900*1350 | 2150*1800*1350 |

* We reserve right to change specifications without prior notice.